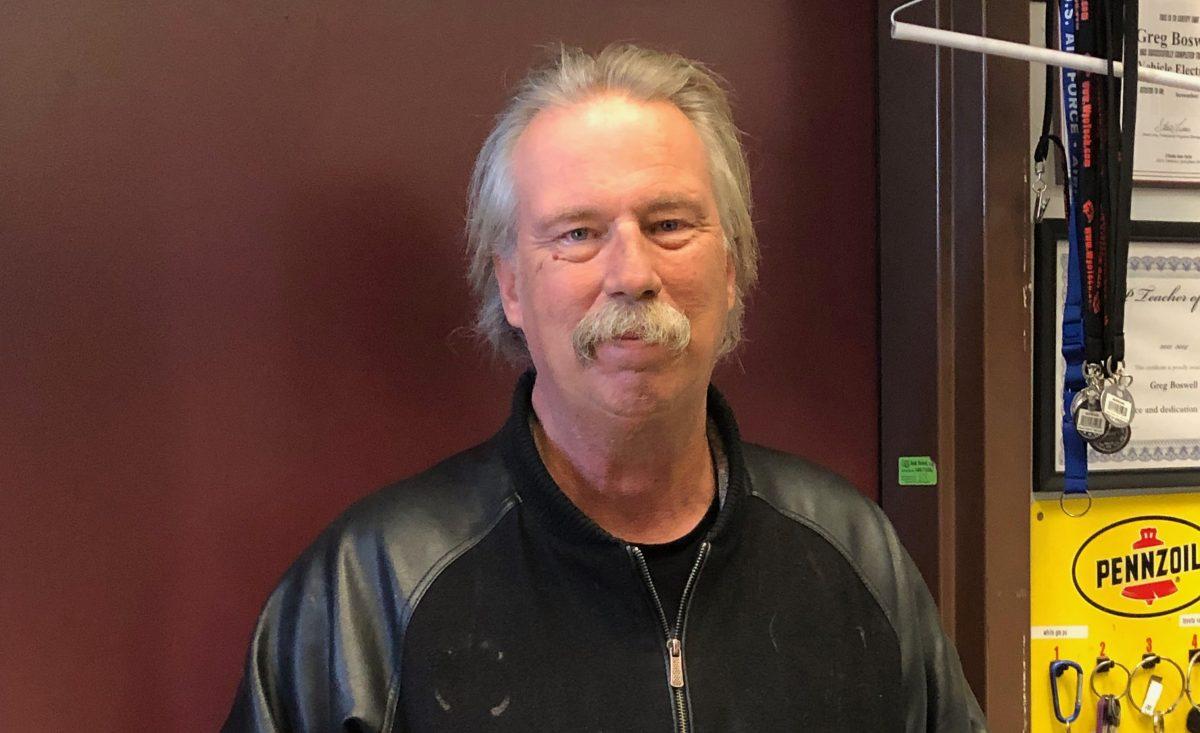

PRHS auto teacher Greg Boswell discusses the departments’ continued success.

This February, the PRHS welding and auto departments again passed their biannual mandatory safety check by the county, according to auto teacher Greg Boswell.

The annual inspection, which these departments have passed since they were introduced to PRHS, ensures that the work areas are safe for both the environment and for students. Fields reviewed include products such as gasoline, diesel, petroleum products, chemicals, and paints. Furthermore, inspectors ensure that each field is taught to students safely and with skill, as well as a general check-up of facilities and supplies, Boswell said.

“This is only one of about five or six inspections a year. The county comes in and inspects for hazardous materials; the fire department comes in and makes sure that we’re safe on the fire end of things; the school district themselves come in at least twice a year and inspect us for safety,” he explained. “…It’s just part of the business of running a shop.”

Despite the rigorous and frequent nature of the examinations, Boswell reported that there’s always a bit of room to improve if things appear to be in working order but would improve with additional maintenance. In his workshop’s case, he mentioned that picking up more oil would be in order, although the shop still has enough to work with for the rest of the year. Boswell also notes that upkeep of books, supplies, and tools are essential to maintaining a clean record of safety and professionalism from the auto and welding classes.

“A clean shop is a happier shop, anyway, and it’s more productive in any business, whether it’s a classroom – this [auto] shop just happens to be a classroom. Anywhere you work, you should be keeping it clean because it’s a safety issue.”

[envira-gallery id=”35789″]